Achievements

Energy Projects

“El Cielo” and “La casa del sol”

Solar Park Projects

As a significant renewable energy investment by COMPLEX in Tepeyahualco, Puebla, Mexico, the initiative aims to support local clean energy development and reduce carbon emissions, with two solar parks boasting capacities of 179.5 MWp and 181.8 MWp, respectively, for a combined capacity exceeding 360 MWp.

The project was executed by China Gezhouba Group Co., Ltd., an engineering, procurement, and construction (EPC) contractor. The company will oversee all project stages, from design to procurement and construction management, ensuring completion by November 2026. The total contract value is $388,841,384, highlighting the project’s importance in strengthening China-Mexico collaboration and advancing the global green energy transition.

CCC Manzanillo III

Initiated by the Federal Electricity Commission (CFE) and located in Manzanillo, Colima State, Mexico. The project will build a combined cycle power plant with a power generation capacity of 346.10 MW to improve the reliability and sustainability of local power supply. As the engineering, procurement and construction (EPC) general contractor, Harbin Electric Group is responsible for the overall implementation of the project, from equipment procurement to engineering construction, ensuring that the project is completed on schedule.

The total project contract value is US$320,895,000 and is scheduled to be completed in September 2024. Once completed, the project will significantly enhance the capabilities of regional energy infrastructure, support the development and modernization of the national power grid, and provide stable support for the local economy and energy needs.

Water Projects

Durango Wastewater

Treatment Plant

The Durango Wastewater Treatment Plant, commissioned by the Water of the Municipality of Durango, represents a significant investment in sustainable water management, with a total contract value of approximately USD 50 million. This state-of-the-art facility is designed to operate efficiently over 25 years, ensuring the long-term health and safety of the community’s water resources. The plant incorporates aerobic and anaerobic treatment processes, handling a flow rate of 1,600 liters per second, alongside an anaerobic cogeneration system designed for 2,000 liters per second. This innovative project enhances wastewater treatment capabilities and promotes environmental sustainability through energy recovery and resource efficiency.

The Tunal II Dam Projects

The Tunal II Dam is a vital infrastructure project in Durango, designed to enhance the region’s water supply and management capabilities. With a maximum storage capacity of 181.40 cubic hectometers (Hm³), the dam serves multiple purposes, including providing drinking water, supporting irrigation efforts, and offering flood control measures. This comprehensive approach ensures the availability of safe drinking water for the community, promotes agricultural productivity, and safeguards against potential flooding, making the Tunal II Dam an essential asset for sustainable development in the area.

Desalination

Reverse Osmosis Technology

– Shuqaiq Phase III, Saudi Arabia –

Daily Capacity: 450,000 m³ of potable water

Technology Used: Reverse Osmosis (RO)

Infrastructure Highlights:

• Deployment of over 7 km of HDPE pipelines

• Large-scale piping: 2.2 meters in diameter (x4)

Key Outcomes:

• Potable water supply for over 1.8 million people in southwestern Saudi Arabia

• Direct contribution to national water security

• Flagship project implemented in an arid region with chronic water scarcity

Membrane Technology

– DF Film for Yuegong-1 –

This system features next-generation membrane technology, designed for large-scale desalination solutions:

• Microfiltration, ultrafiltration, and selective nanofiltration (DF) under ultra-low pressure enable precise contaminant separation with minimal energy consumption.

• Closed-loop water regeneration cycle leveraging plant transpiration and vapor collection, which is then condensed and purified through DF membrane technologies.

• Advanced purification process transforms condensed vapor into potable and hygienic-grade water.

• Full reuse of treated sanitary wastewater through membrane bioreactors, reintegrated into the plant irrigation system.

Sponge City Initiatives

Tianjin – Jiefang South Road

An iconic project comprising over 21 integrated subprojects, including:

• Primary treatment of stormwater runoff

• Renovation of 13 urban roads <

• Development of urban parks <

• Implementation of smart pipeline networks across 4 residential zones

Results:

• Annual runoff control exceeding 75%

• Rainwater reuse rate above 6%

• Removal of suspended solids (SS) exceeding 65%

Xichong – Sichuan

A comprehensive transformation of a mountainous region through the modernization of wastewater networks and the implementation of sponge infrastructure around Lianhua Lake.

Results:

• Significant enhancement of the urban landscape, integrating ecological and cultural elements

• Improved living environment and overall quality of life

• A scalable model for rural and semi-urban communities in complex terrains

Wastewater Treatment Projects

Shunyi Olympic Support Project

– Beijing

• Capacity: 100,000 tons/day

• Technology: MBR (Membrane Bioreactor) + Chemical Flocculation

• Water quality upgraded to meet Class III standards

• Integrated system including pumping stations, intake structures, and distribution networks

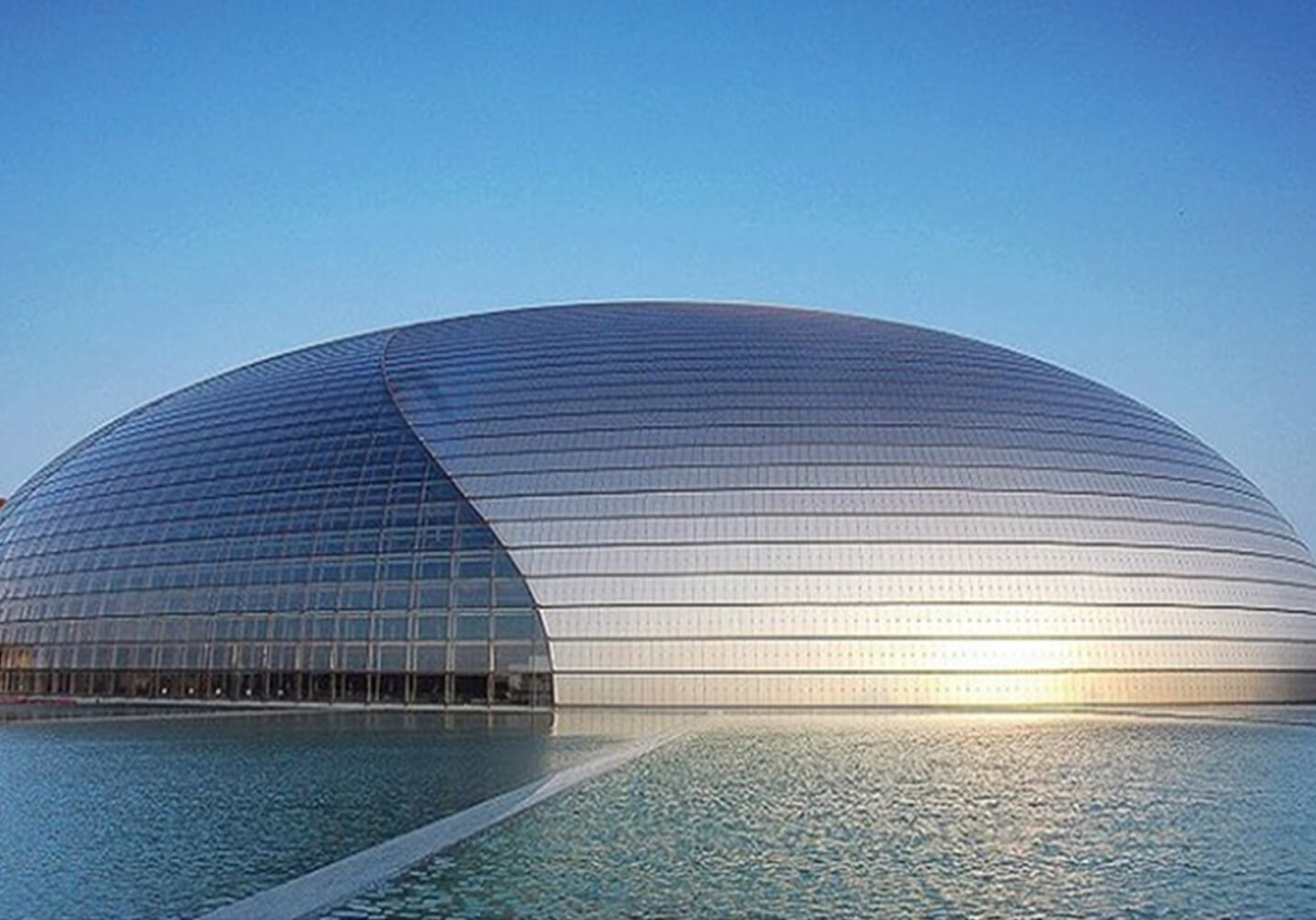

National Centre for the Performing Arts – Beijing

• Capacity: 50,000 tons/day

• Efficient water recycling technology

• Reuse of landscape water for domestic purposes with potable quality standards

• In continuous and stable operation since 2006

Mentougou Plant – Beijing

• Capacity: 40,000 tons/day • MBR technology

• Supplies over 14 million tons of recycled water annually

• Operated under a 25-year concession model – a replicable solution for Mexico

Leadership in Hydraulic Infrastructure

Three Gorges Project – China

Gravity Dam | 181 meters high | 22,400 MW

Storage Capacity: 39.3 billion m³

• Advanced technologies in concrete cooling, sluice gates, turbines, and intelligent control systems

• Eliminated flood risks along the Yangtze River and redefined the regional water management system

Gezhouba Project – China

Gate Dam | 2,715 MW

The first major dam on the Yangtze River; served as the technical foundation for future megaprojects

Competitive Advantages:

• Cutting-edge capabilities in river closure, large-scale turbine installation, and structural thermal control

• State-of-the-art construction equipment

• Internationally experienced technical and management teams

Marketing & Media Projects

Supporting brand ing in

Latin America

In August 2024, through its subsidiary Voyage Media SA de CV, Jolla International successfully planned and executed a corporate event in Mexico City for international clients, providing comprehensive planning, logistics, and management services showcasing exceptional professionalism. This included arranging group accommodations, catering, and venue services at four luxury hotels in Mexico City, coordinating hundreds of high-end business vehicle transfers, organizing over 40 bus services, and offering comprehensive event production support and high-level security services. The event attracted more than 1,000 participants worldwide, and our impeccable attention to detail and smooth operations ensured attendees a seamless, efficient, and unforgettable experience. Our team members, fluent in English, Spanish, Chinese, and Japanese, are dedicated to providing top-tier customer service that meets the high standards expected by our clients.

Nearshoring Advisory Projects

Sinbon Electronics Smart

Factories Project

On August 27, 2024, Xinbang Electronics officially awarded and commenced construction of the first phase of the intelligent SLP Xinbang factory in the Logistik II industrial park in San Luis Potosí, Mexico. ELUFA SA de CV, a wholly-owned subsidiary of Jolla International Group, played a key management role in the project. This intelligent factory project covers over 80,000 square meters. It aims to enhance Xinbang Electronics’ competitiveness in the global market, optimize the global supply chain, shorten delivery times, and improve production efficiency. ELUFA, leveraging its extensive experience and local resources, ensures the smooth implementation of the project in terms of schedule, quality, and cost control. This collaboration not only reinforces Jolla International’s bridging role in Sino-Mexican business cooperation but also injects new momentum into Mexico’s industrial upgrade and economic development.

Technology Integration & Engineering Solutions Projects

Phase 1 of the SINBON Electronics (SINBON) SLP Smart Factory Project in Mexico

Location:

San Luis Potosí

Scale:

Phase 1 has a construction area of 13,600 square meters ,Landscape and earthwork with 40,000 square meters.

Construction period: Oct. 2024 to 2025 Apr.

Contract scope: Turn-key EPC, permit application.

Phase 1 LIZHONG GROUP MEXICO

Location:

Nuevo León

Scale:

Phase 1 has a construction area of 60,000 square meters, with a total of 10 units, the largest of which is 55,000 square meters.

Phase 2 has a construction area of 25,000 square meters, with three units, including a 4-story frame concrete structure office building and 2 factory buildings.

Construction period

Mar.2022 till Mar.2025

Contract scope:

Turn-key EPC, permit application.

ZHENDE MEDICAL MEXICO

Location:

Carretera Saltillo- Zacatecas 47 Km

Scale:

Building area is 50,000 square meters, with two units, a 12,000 square meter workshop and a 24,000 square meter warehouse.

Construction period:

Mar.2025 to Aug.2025

Contract scope:

Turn-key EPC

Phase 1 of the C5I Command Center Project in Ciudad Juárez, Chihuahua, Mexico

development and execution of Phase 1 of the C5I Command Center, a high-impact security and intelligence infrastructure project in northern Mexico.

This phase encompasses a comprehensive EPC (Engineering, Procurement, and Construction) scope, including:

- Specialized civil works and structural engineering

- Advanced HVAC systems tailored for mission-critical operations

- High-end equipment supply and integration

- Installation of secure communication systems and intelligent control technologies

- End-to-end project management ensuring compliance, precision, and rapid deployment